Supplier Management Best Practices

Digital technologies have permitted organizations to conduct business across international boundaries with ease. To remain globally competitive, organizations must maximize the advantages offered by supplier management best practices to ensure they remain efficient in their procurement.

On this page:

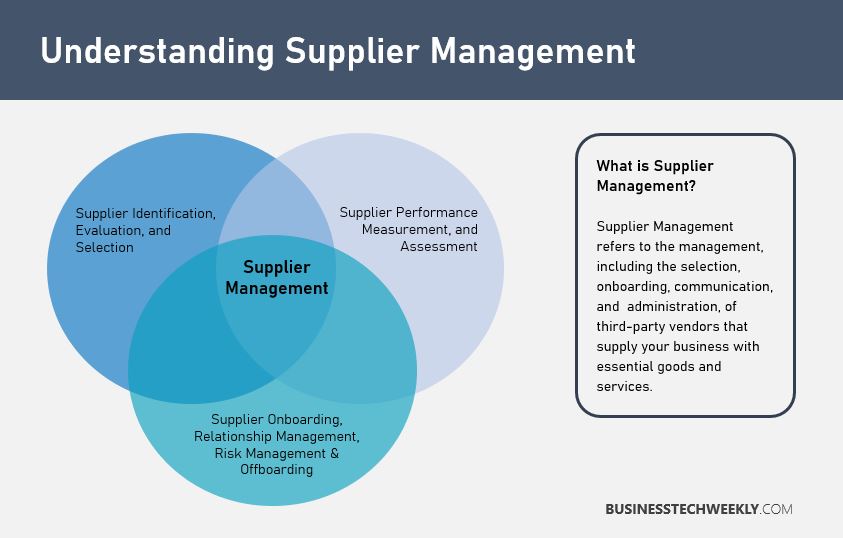

What is Supplier Management?

Broadly, supplier management refers to the efficient, and effective, management of third-party vendors which supply your business with essential services, goods, or works.

Supplier management included identifying, and selecting suppliers, and managing their performance to maximize their value for your business, by ensuring they deliver to your business’ requirements.

Effective supplier management allows businesses to account for why money is being spent and with whom, by ensuring their suppliers deliver the quality of goods, works and services that were promised.

Why is Supplier Management important?

In today’s globalized digitally connected world, even small and medium businesses are exposed to international supply chains and a supplier base which consist of several third party vendors. All this leads to an increased level of complexity when managing numerous suppliers.

To reduce this complexity, businesses often focus on their most strategic suppliers. While this approach may be tempting, it may not be the best approach for all your suppliers, and may inadvertently increase risk.

This increased risk may expose your business to disruption and unpredictability, severely impacting your ability to meet deadlines or customer demands.

Since your business is only good as your suppliers, implementing supplier management processes will provide several advantages:

- Improved predictability and insight into your supply chain

- Better informed business decisions

- Capability to avoid disruption

- Reduce risks of introducing a new supplier to your business

- Access to higher-quality products and valuable insight into when essential goods will arrive

What are the Benefits of Supplier Management?

Businesses who have implemented supplier management across their operations have experienced several benefits. While the realization of those benefits varies, they each play a crucial role in helping your business achieve its goals.

The benefits that effective supplier management can provide are:

- Access to higher-quality services and products – Effective supplier management, through regular evaluation and assessment of supplier performance, will help ensure your vendors deliver the best service and product they can, ensuring your business’ requirements are being met.

- Reduced risk and costs – Robust supplier management reduces risk by decreasing the likelihood of invoice fraud, between employees and vendors, and further minimizing risk when introducing new vendors. Finally, by taking advantage of discounted, fixed or scaled pricing, businesses can minimize risks associated with volatile pricing, while introducing cost savings.

See also: IT Risk

- Business continuity through supply chain resilience – A core principle of supplier management is risk management in relation to managing your supply chain. As part of supplier management, you should involve third party vendors in your business continuity planning to determine alternative plans, while, where possible, meeting obligations.

- Achieving compliance requirements – With increase cyber-threats, businesses have been subject to increasing levels of compliance. The inclusion of risk assessments in your supplier management process will help you identify potential risks and implement mitigation before they become a significant problem.

Make sure you are aware of the different standards, regulations and legislation your suppliers may need to be compliant with.

- Ability to make better-informed business decisions – One of the objectives of supplier management is to improve decision making within your business by providing valuable insight into your supply chain to minimize disruption, risk and delays, allowing you to better meet customer demands.

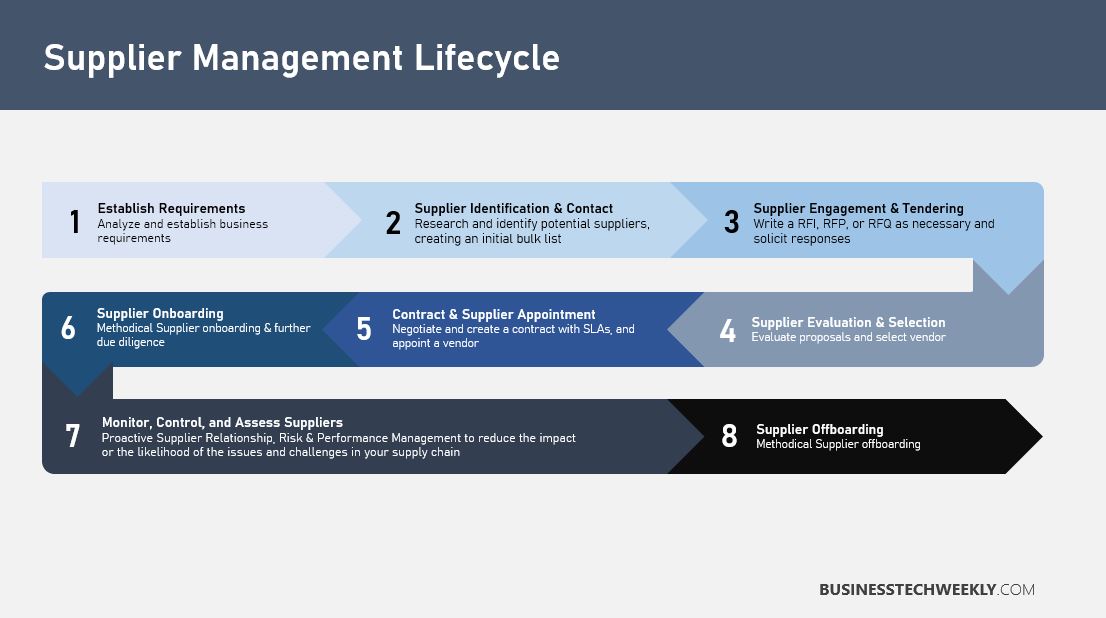

The Supplier Management Lifecycle

The supplier management lifecycle, (or sometimes vendor management lifecycle), monitors all suppliers for optimal performance, adherence, and transparency during their time under contract.

While several variations for supplier management exist, most supplier management frameworks will commonly cover eight distinct but interrelated activities:

Note: The pre-Contract Phase, covering needs identification and solicitation, steps one to four, is covered in-depth in Finding a Technical Supplier for your Business, which details business requirements analysis, issuing RFPs and RFQs, and supplier selection criteria.

Both ITIL and the Chartered Institute of Procurement and Supply (CIPS) have useful resources for developing a Supplier Management framework tailored to your business.

Below, we cover the remaining phases for onboarding, performance and risk management, and offboarding.

Supplier Onboarding

Having conducted the necessary due diligence during the technical supplier selection, you would have signed a contract with a supplier for goods, services or both. The next step after contract signing is supplier onboarding.

The purpose of this phase of the supplier management lifecycle is to collect detailed information to provide multidimensional data for the monitoring and analyzing of supplier performance during their contract.

A supplier onboarding process will strengthen your business relationships, and also help you to:

- Decrease risks, by cutting out intermediaries and reducing human error

- Streamline processes and increase efficiency by reducing redundancies

- Ensure compliance with regulations, by tracking data and workflow

- Decrease the time to approve and activate new suppliers

Nurturing your vendor and supplier relationships provides a robust foundation to your supplier management program. It is often the first step to building crucial business partnerships with your vendors.

Supplier Onboarding Checklist

Having a basic checklist to walk through with each new supplier helps ensure that you capture the crucial details right from the start of the relationship.

You may find that you have captured, some or all, of the below information during the technical supplier selection. If so, the information needs to be refreshed and re-validated. The following supplier onboarding checklist is provided as a guideline:

Supplier Onboarding Steps |

Checklist |

Supplier EvaluationThe first step in onboarding consists of supplier review and risk assessment

|

|

Supplier approval and requirementsDiscuss the following to clarify expectations and requirements before finalizing approvals

|

|

Supplier info and data sharingDepending on how in-depth your form is, you may need to collect the following data for each supplier |

|

For effective supplier onboarding and activation, make sure your accounts, purchasing, and warehouse teams are provided with the supplier details and requirements.

Tips for Supplier Onboarding

The following tips will help you define a supplier onboarding process as part of your supplier management framework:

- Automate processes where possible – Onboarding a new supplier can be complicated. Identifying opportunities to automate tasks will help reduce human error and increase efficiency. For example, consider creating an online supplier application portal where each vendor can input their information themselves.

- Designate a point person to manage onboarding checklists – With so much information to review and verify, it’s easy for documents and data to be misplaced. Appointing a single person to verify checklist(s), will help to avoid miscommunication or mistakes.

- Use the onboarding process as a guideline – Maintain flexibility by adapting to each unique supplier relationship.

- Set expectations – Ensure your suppliers understand your expectations for lead time, pricing, payment, product quality, and other factors.

- Regularly review supplier information – Ensure you have the latest and correct data relating to your suppliers. Within your onboarding process, you should stipulate the need for your vendors to refresh and confirm the submitted information.

Supplier Risk Management

As supply chains become increasingly complex, businesses need to be proactive in performing supplier risk assessments, to protect against the risk, which can plague your supply chain, reduce costs savings, and disrupt performance.

Supplier risk assessments can be performed at the time of onboarding, covering financial, operational, data security, and regulatory risks. Supplier risk assessments can be performed using a structured Risk Assessment Methodology.

Businesses change and mature, and your suppliers are no different. Consequently, any supplier risk assessments should be reviewed periodically to ensure it remains current. Implementing KPIs are an effective way of regularly assessing this. We’ll explain KPI’s in more detail in the next section, “Evaluating supplier performance”.

When assessing supplier risk, there are seven areas you should consider:

- Financial stability – Businesses should use a credit bureau to establish a financial risk score for each supplier. You can ask the supplier to provide this information as part of the onboarding process.

- Insurance – Ensure to confirm and verify that your supplier has adequate insurance. Asking your supplier to provide a copy of their insurance certification(s) annually will ensure you remain aware in the event a supplier no longer has insurance.

- Reputational protection – Regularly monitoring media sources for adverse news stories about your suppliers, will ensure your business is not associated with negative publicity through association with a particular supplier.

- Compliance – Businesses can monitor regulatory compliance risks through global watch-lists and document validation. While regulatory risks may be out of a supplier’s control, businesses need to remain vigilant as to whether their suppliers are in breach of any regulatory compliance.

- Cybersecurity – Cybersecurity risks are one of the most components that businesses have been seeking help within recent years. Your approach to supplier risk management may need to include the ability to produce a security rating for suppliers, possibly through a security questionnaire.

- Social responsibility – Assessing your supplier’s efforts to combat social responsibility risks should include anti-slavery and human trafficking, diversity verification, and sustainability analysis. Similar to reputational protection, its crucial to your reputation that your business is not associated with vendors that rank negatively for these issues.

- Health and safety – If your supplier provides onsite resources for your business, your overall health and safety status will, in part, be determined by your supplier’s adherence to health and safety standards. Aggregating and managing information such as the Occupational Safety and Health Administration (OSHA) statistics and other materials will help assess these risks.

See also: Technology Risk Management

Evaluating supplier performance

As part of the supplier management process, you need to periodically evaluate the supplier’s performance to determine whether they are fulfilling the agreed objectives.

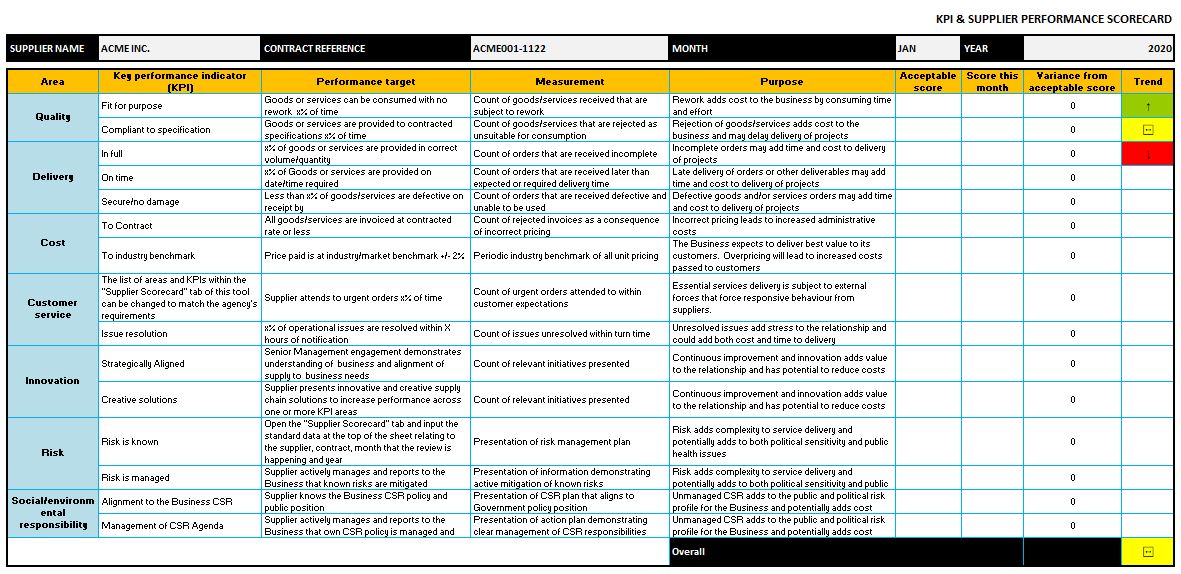

Establishing key performance indicators (KPIs) to measure performance will help in identifying problem areas. KPIs will also provide valuable insights to maximize supplier performance, and inform you of the effectiveness of your overall supplier management process.

Creating KPIs to Evaluate Supplier Performance

KPIs and SLAs are both important components for analysis and measurement. For supplier performance (and risk) management, KPIs need to be as objective as possible. Effective KPIs should answer four key questions:

- What is being measured?

- Who is measuring it?

- At what intervals is it being measured?

- How frequently is this data being reported?

Numerous factors will determine your actual KPIs, for example, your industry, supplier contract, and the size and type of supplier. However, there are several common categories which can be used to assess supplier performance:

- Quality – Is the service or product of satisfactory quality and value? How often is there an issue with unsatisfactory service or products?

- Delivery – Do deliveries arrive intact and on-time? Does the supplier have the capability to provide larger, complex, and emergency orders? How often are deliveries damaged, delayed, or lost?

- Cost Savings: Does the vendor leverage economies of scale to optimize pricing for you? How often does the supplier raise their prices?

- Customer Service: How quickly and thoroughly does the supplier respond to, and resolve issues? How effectively does the supplier communicate? How are complaints managed, including any escalation?

- Expansion and Innovation: Does the supplier follow continuous improvement processes? Does the supplier provide additional strategic value by recommending new or different products, services, tools, or processes to reduce costs, improve quality, or expand features?

- Risk Assessment – Is the service (or product) provided in compliance with all applicable legislation? Are the raw materials ethically sourced?

The measures, objectives and targets used in monitoring the supplier’s performance must reflect those that were agreed when the contract was let.

Good quality key performance indicators (KPIs) should be discrete, easily understood, and provide sufficient data to facilitate swift analysis of the current situation, and be ultimately relating to your business objectives.

You should assess the relative importance of each KPI, assign numerical weighting and agree scoring guidance:

Defining and monitoring KPIs for supplier compliance and performance allows you to react, develop and execute any contingencies to unacceptable third-party risk exposure or prevent supply chain disruptions.

In addition, monitoring supplier performance allows both parties to exploit any opportunities for growth, new markets or new products and services.

Managing KPI Breaches

You should also consider the consequences if suppliers fail to meet KPIs. In most cases, breaching KPIs may only result in a review followed by a plan to improve performance. In such cases, the SLA is merely an aspirational document.

You may want to consider how many infringements are acceptable before the consequences are triggered. The number of violations required to trigger a consequence should depend on the goods and services being delivered, the effect non-compliance has on your business, and the KPI being measured. For serious projects, one or more infringements may lead to contract termination.

Alternatively, you may decide to provide the supplier with some margin. In this case, the consequence will only be triggered when the supplier breaches a KPI for two consecutive months, or for seven out of twelve months. A further alternative is to state a metric so that it only needs to be met 80% or 90% of the time.

Post-Contract Phase – Supplier Offboarding

The complexity of this phase will be governed by the role played by a particular vendor within your supply chain.

Suppliers who are short-term or low-performing can be offboarded in a straightforward manner. Suppliers engaged on long, complex, and high-value contracts, may require more time and attention to offboard.

The purpose of this phase of the supplier management lifecycle is to ensure all contractual obligations have been met by the supplier. Any additional commitments are also reviewed and recorded for monitoring, such as service agreements and warranties which extend beyond the life of the contract.

Once contract completion has been verified, supplier offboarding can be completed. Supplier offboarding typically completed with the help of a supplier offboarding checklist.

For example, an offboarding checklist may include:

- Advising all relevant stakeholders of contract completion

- Obtaining confirmations that the supplier has complied with all buyer stipulations, industry standards, and relevant laws throughout the contract

- Removal of supplier access to physical and virtual systems and assets

- Final payment confirmation, including the confirmed suspension of any additional payments other than those specified by post-contract stipulations

- Final supplier evaluations, including performance data, and any contextual information relating to the end of the contract, e.g. Was the contract terminated or completed? Were the terms of the contract met? Were there interpersonal issues experienced? Did the supplier meet the terms of the agreement, but failed to achieve the value or savings forecasted?

Five Key steps to successful Supplier Management

When implementing supplier management within your business, the following steps will be crucial in establishing a wide-reaching framework:

- Ensure commercial coverage – Make sure you have commercial coverage with your vendors by agreeing and drawing up legal contracts with your suppliers.

- Set expectations – Communicate what you expect to receive from third-party vendors. Outline your expectations in terms of standard and quality of service and product. You can set expectations through SLAs. Identify next steps if standards fail to meet your expectations.

- Create and define internal policies – Define internal policies and processes for supplier management and governance, including selecting suppliers, measuring performance, and onboarding and offboarding vendors. Ensure employees who contribute to supplier management understand these policies.

- Regularly meet with your suppliers – For supplier management to succeed, you should actively manage your vendors. Additionally, arrange regular meetings to discuss progress, issues and resolutions, and potential challenges. Maintaining regular contact with your suppliers crucial to ensure you have insight into the wider supply chain.

- Maintain performance metrics – Keep complete and accurate records of supplier performance and review them regularly. These can be used to forecast potential challenges in your supply chain, and negotiate better terms at the time of contract renewal.

Does your business need Supplier Management?

While supplier management is often seen as exclusive to large firms, businesses of all sizes and in all sectors will, at some point, procure goods, services or works from third-party suppliers.

A well-structured supplier management process will allow you to:

- Gain meaningful insights into your supply chain, by streamlining data from multiple sources

- Collaborate with your suppliers to improve supplier relationship management

- Monitor your suppliers’ capabilities to meet your business’ current and future demands

- Evaluate risks in your supply chain and implement mitigating measures

In terms of efficiency, effectiveness and experience, the success of your procurement process will be determined by your approach in engaging, communicating, and managing your suppliers.

Ensuring you are able to manage your suppliers effectively, by implementing a practical supplement management framework, should therefore be considered carefully.